ETHYDCO Showcases New Plastic Solutions Through Product Development

Sat, 20-Dec-2025

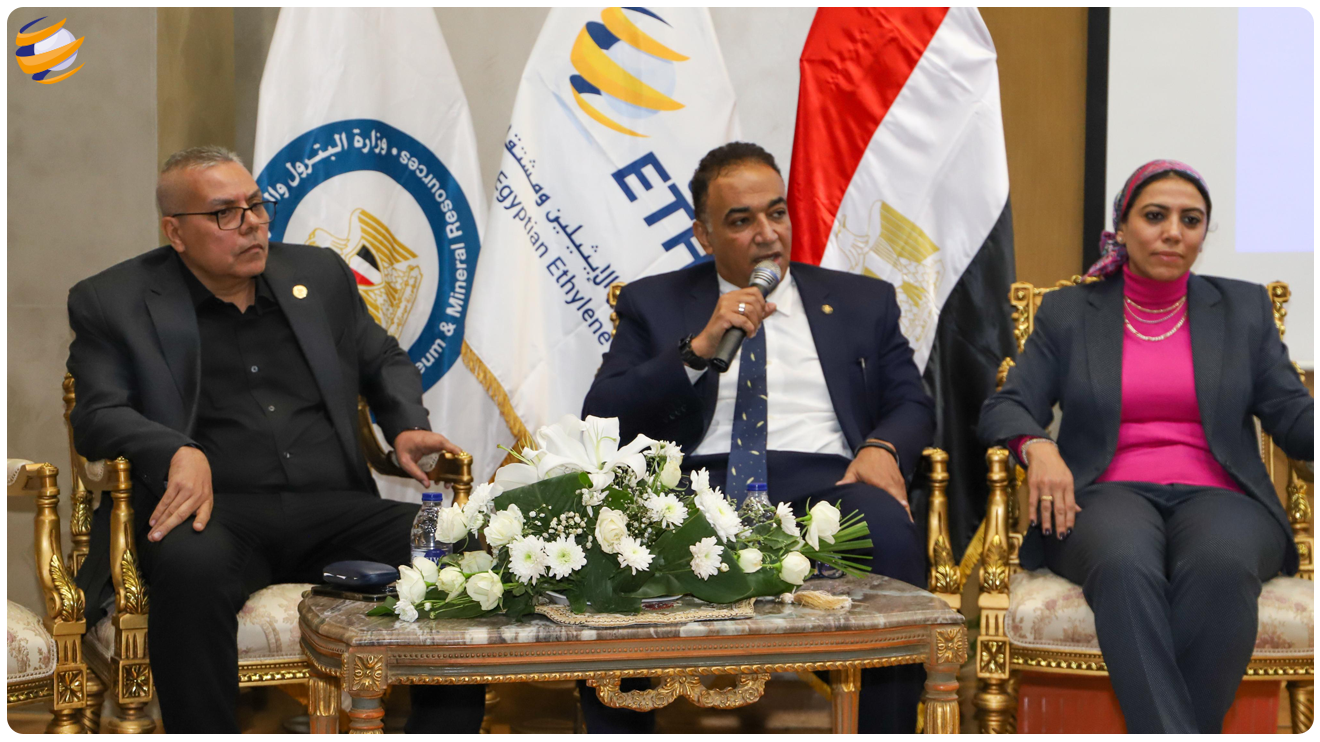

In line with the State’s direction and the

efforts of the Ministry of Petroleum and Mineral Resources to strengthen

national industry, maximize local content, and reduce the import bill, the

Egyptian Ethylene and Derivatives Company (ETHYDCO), during its annual meeting

with local market customers, including manufacturers and distributors, unveiled

a new plastic raw material specifically designed for blow molding applications,

EM-5525-AAH

.

The new product serves key industrial sectors,

particularly companies specializing in the manufacture of motor oil and

automotive lubricant containers.

This launch represents a qualitative leap in

plastic products manufacturing, as the new grade features specifications that

make it essential for industries requiring high quality,

durable solutions with strong resistance to chemical impact, while

simultaneously complying with international safety and sustainability

standards. The product is expected to open promising prospects for the

manufacture of industrial storage containers and many other applications for

years to come.

During the meeting, Eng. Heba Abdel Qader, Assistant

Chairman of the Petrochemicals Holding Company for Marketing for Marketing

,

praised ETHYDCO’s new product, highlighting that it aligns with the integration

strategy among petrochemical companies aimed at maximizing the added value of

Egypt’s resources and wealth. She emphasized that ECHEM’s support for ETHYDCO

contributes to opening multiple production and marketing channels, and that the

new product represents a clear example of this successful integration.

Chemist Hesham Riyad, Chairman and Managing

Director of ETHYDCO, affirmed that innovation and development

represent a continuous journey at ETHYDCO, stressing the company’s ongoing

efforts to develop new plastic solutions through cooperation and integration

among all technical departments.

He extended his sincere thanks and appreciation

to all ETHYDCO employees who contributed to this achievement, as well as to all

national partners of success manufacturers and

distributors of the company’s products emphasizing that the

new product comes within the framework of ETHYDCO’s plan to enhance its

production capabilities and strengthen the competitive value of its products.

He further stated that the local market will be

given priority during the current period in supplying the new product to meet

its needs. He also noted that during the current year and recent years, the

company has doubled the quantities directed to the local market to meet the

rapidly growing demand, which required focusing on products with the highest

market needs.

Attendees listened to a presentation highlighting

the importance of the new product for local market customers, along with market

trials conducted in cooperation with a group of leading oil container

manufacturing companies. These trials demonstrated the product’s ability to

meet operational requirements, enhancing confidence in locally produced

materials and reducing reliance on imported raw materials.

The meeting also featured an open discussion

session during which ideas, opinions, and proposals were exchanged, customer

needs were identified for fulfillment, challenges were discussed for

resolution, and customer satisfaction with the company’s products was assessed.

At the conclusion of the meeting, distinguished

customers in the manufacturing and marketing of the company’s products were

honored in appreciation of their efforts and fruitful cooperation throughout

the year. The event concluded with a tour of the packaging center and

polyethylene laboratories, where local market customers were briefed on the

complete inspection and testing processes applied to raw materials used in

production, culminating in a final product fully compliant with quality and

sustainability specifications.